Design and Manufacturing

Our bolted steel tanks are available in the following shapes:

They consist of galvanised steel, stainless steel and aluminium sheets which are processed in the factory according to a Blue Tank standard and assembled on site by bolting.

Standard features

- Aluminium caged ladder with an access platform of 1200 x 800 mm

- 3 KW resistor for tank freeze protection

- Convection chamber

- Drain valve DN80

- Hydrostatic pressure gauge

- Overfill prevention sensor

Options

- Architectural quality powder coated paints (colour chosen by the customer)

The bolts of the tanks are then provided with nut covers of the same colour. - Tank insulation

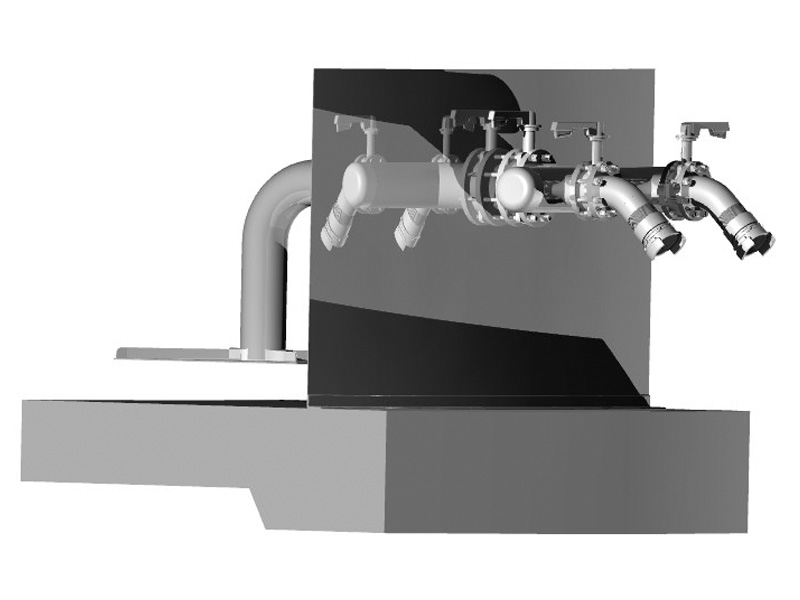

- Other equipment to be defined with the client

Capacities of our tanks

Calculation tool

These capacities are given as an indication. They may vary according to the standards taken into account.

Our design office

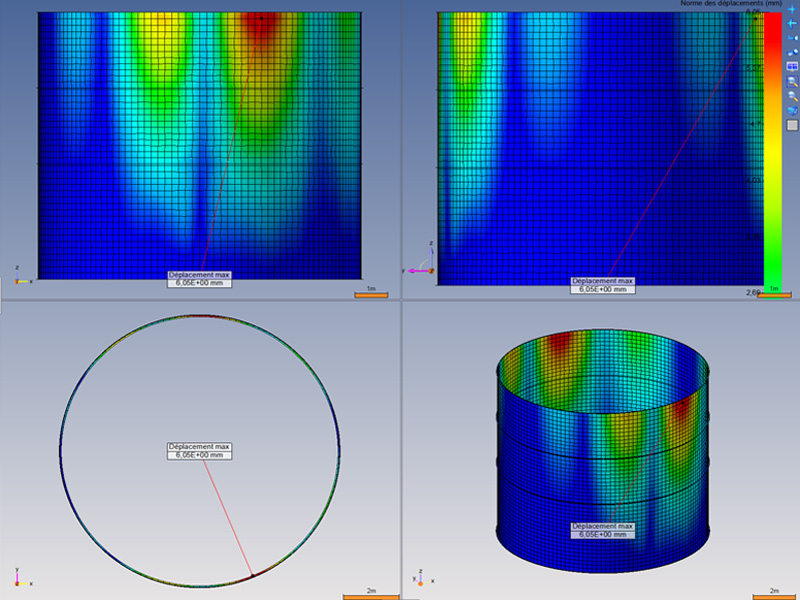

Equipped with CAM software (Computer Aided Manufacturing), CAD (Computer Aided Design) and finite element calculations:

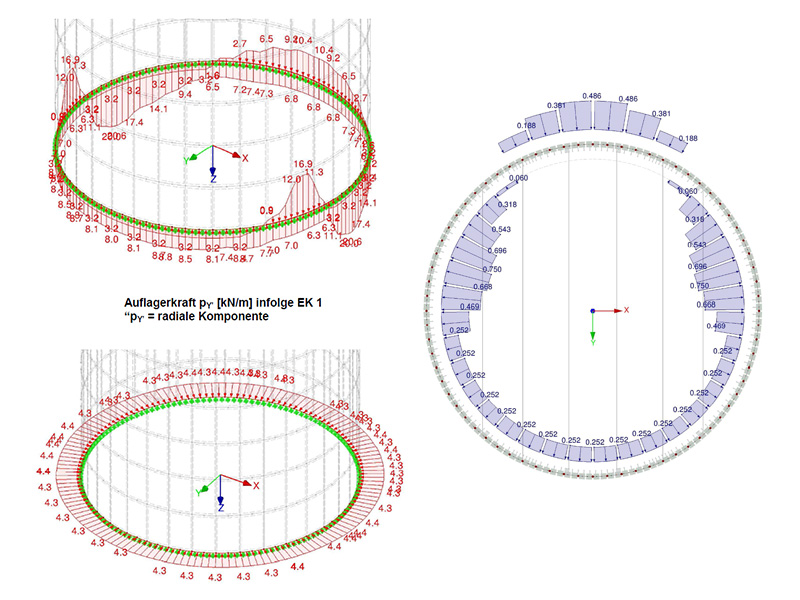

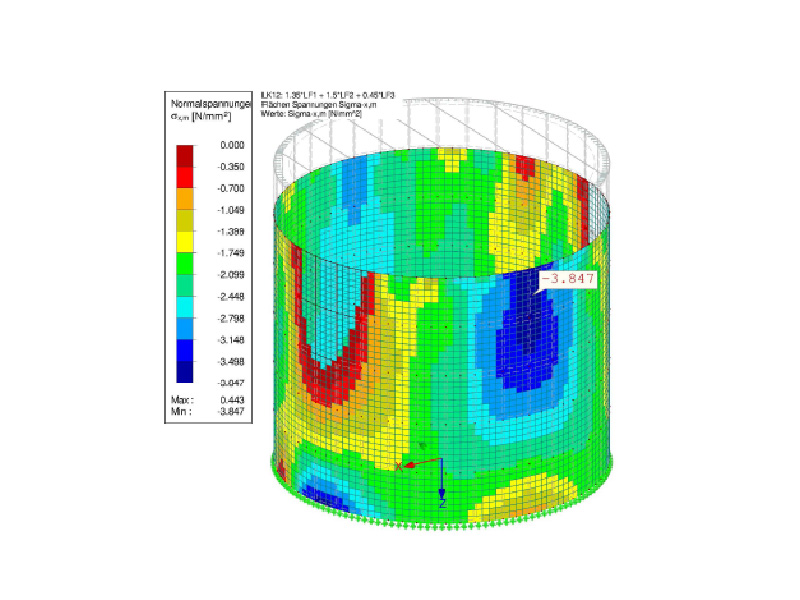

Calculations according to Eurocodes, AWWA, Seismic Zone EC8...

Customised calculation notes by case for a wind study of the tank, in empty configuration, according to Eurocodes. Max stress and displacement verification

Load distribution for the design of the base: seismic moment, hydrodynamic pressure on the surface of the base, anchors...

Tanks in seismic zones: learn more

Our manufacturing plant

The entire tank manufacturing process is carried out at our Solferino plant in the Landes.

We have production tools composed of high-performance machines:

- CNC punch press with loader

- Profile bending machine

- Sheet metal bending machine for large thicknesses

- Plate rolling machine

- Press brake

- Punching bench with profile

- Welding station

- ...